Cardan Shaft & Cooling Tower Shaft Alignment

Cardan Shaft & Cooling Tower Shaft Alignment

Cardan Shaft Alignment

What is Cardan Shaft Alignment?

Drive shafts, sometimes referred to as cardan shafts, are crucial for transferring torque between parts that are not precisely aligned. The risk of mechanical problems is decreased by proper alignment, which guarantees smooth operation and avoids excessive vibrations.

Correct Cardan Shaft Alignment Is Essential

Cardan shaft misalignment can result in: -

Increased energy usage Unexpected downtime and frequent repair

Our Cardan Shaft Alignment Services

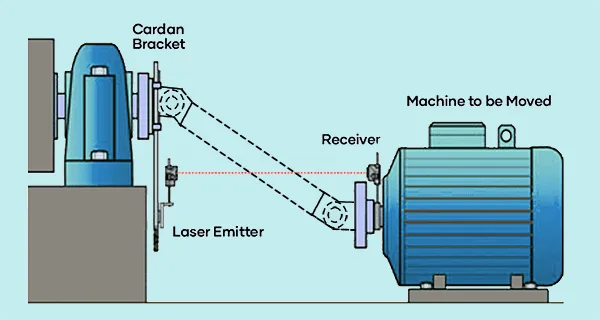

To guarantee accurate Cardan shaft alignment, we employ cutting-edge laser alignment equipment. Among our offerings are:

Alignment of Cooling Tower Shafts

The Significance of Cooling Tower Alignment Shaft

In industrial cooling systems, cooling towers are essential components. Fan and motor shaft misalignment can result in excessive stress, which lowers efficiency and raises maintenance requirements.

Common Problems with Cooling Tower Misalignment

Our Cooling Tower Shaft Alignment Services

Our Services for Cooling Tower Shaft Alignment

Solutions for Precut Shims

Precise adjustments are necessary for proper alignment, and precut shims are essential to attaining precise alignment. Our premium precut shims offers the following benefits:

Precut shims are used in alignment processes to increase machine efficiency, lower vibration, and increase equipment longevity. Our shims are composed of carefully chosen materials that are appropriate for shim application. Every shim's thickness is regulated to be as near to the stipulated value; high hardness and springness minimize the likelihood of thickness changes during use.

Features:

0.01 mm Thick to 5 mm Thk Width: 500 mm to 5 mm Length: 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316H, 316L, 316 TI, 317, 317L, 321, 321H, 347, 347 H, 409, 410, 4105, and 430 are the available coil form grades.

For expert horizontal and vertical shaft alignment services if misalignment is causing problems for your equipment, get in touch with us right now. Our professionals will make sure your equipment operates effectively, smoothly, and with little downtime.